The Clear Advantage: How Tank Transparency Revolutionizes Water Level Monitoring

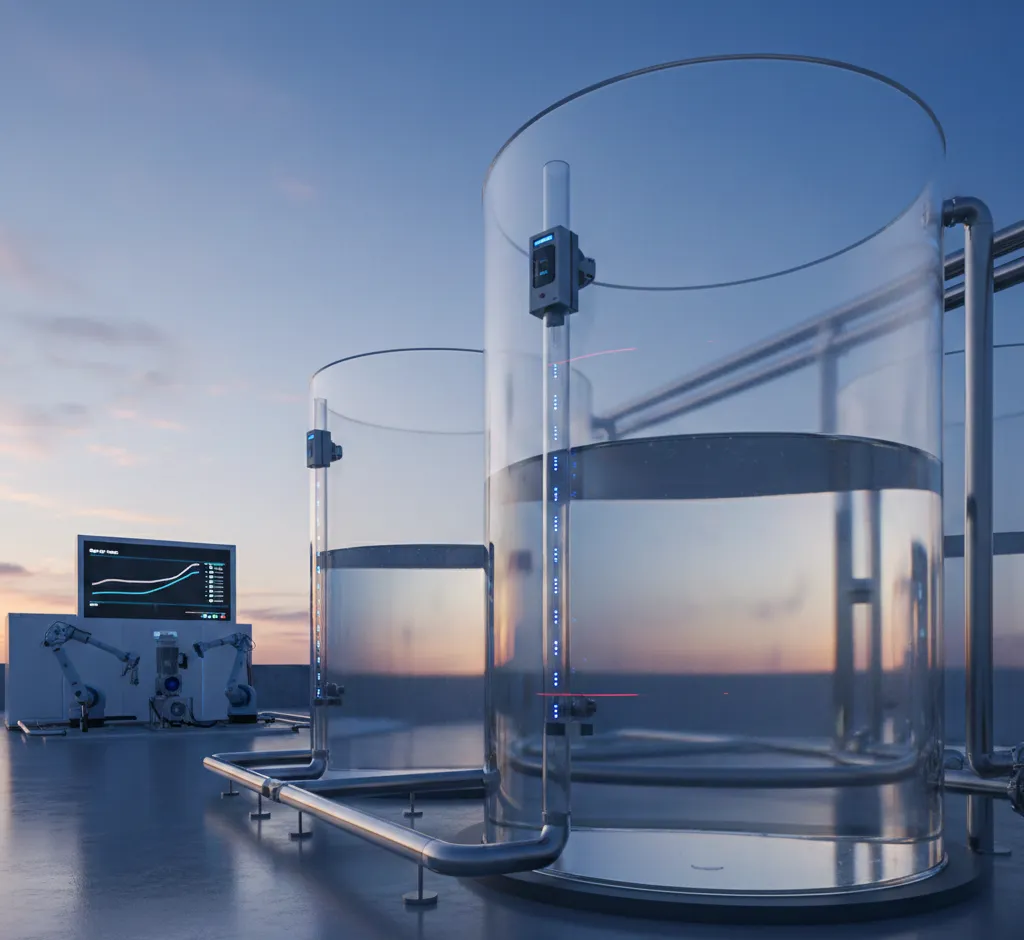

Discover how transparent and translucent tank designs, alongside advanced sight gauge technology, offer a superior, non-invasive method for accurate, real-time water level monitoring and management.

Introduction: The Vital Role of Accurate Water Level Monitoring

Accurate monitoring of water levels in storage tanks is more than just a convenience; it's a critical component of safety, efficiency, and resource management across countless industries—from municipal waterworks and chemical processing to agriculture and manufacturing. Traditional methods, often relying on internal floats, pressure sensors, or manual dip-stick measurements, present challenges like maintenance issues, sensor drift, and the necessity of direct human intervention, which can be time-consuming and prone to error. A revolutionary, yet elegantly simple, solution is emerging: **tank transparency**. This article explores how embracing transparent or translucent tank designs, or integrating advanced transparent gauge systems, provides a clear, reliable, and fundamentally superior method for continuous, non-invasive water level monitoring.

The Core Principle: Visual Clarity as a Monitoring Tool

The concept of using transparency is rooted in the oldest form of measurement: direct visual inspection. When a tank wall is transparent, the level of the contained fluid is immediately and perpetually visible. This overcomes the main drawbacks of internal electronic or mechanical systems. The level you see is the true level—unaffected by sensor calibration, electrical failures, or mechanical fouling. This immediacy translates directly into a higher degree of **operational safety** and **reliability**.

Overcoming Limitations of Traditional Methods

Traditional monitoring techniques, while functional, come with inherent trade-offs:

- Pressure Sensors: Can be affected by temperature, density changes in the fluid, and hydrostatic pressure variations, requiring frequent recalibration.

- Float Switches and Ultrasonic Sensors: Susceptible to fouling (sludge, scale buildup) which can cause sticking or inaccurate readings, leading to high maintenance costs.

- Manual Dip-Sticking: Inherently risky (requires personnel to access the tank top), time-consuming, and provides only intermittent data points.

By contrast, a transparent tank or sight gauge provides a **passive, maintenance-free** visual indicator that can be easily validated against any electronic system, serving as the ultimate fail-safe reference point.

How Tank Transparency Facilitates Automation and IoT Integration

While the visual aspect is paramount, transparency also enhances modern monitoring technology. Instead of placing a probe inside the tank, modern systems use the visual indicator:

- Optical Scanners: Cameras or light sensors can be mounted *outside* a transparent tank wall or sight tube to continuously capture the water level.

- Machine Vision and AI: Sophisticated systems can be programmed to 'read' a transparent gauge or the tank itself, converting the visual water line into a digital data point. This system is non-contact, meaning the sensor never touches the water, drastically reducing the risk of corrosion or contamination.

- Remote Monitoring: The visual data captured by external cameras can be streamed over an IoT network, providing real-time, high-definition level data to operators anywhere in the world.

Material Science and Design: Making Transparency Possible

The feasibility of tank transparency depends heavily on material science, particularly the use of **advanced polymers** and **specialized glass**.

Modern Materials for Water Storage

For large-scale water storage, transparency is achieved primarily through:

- High-Density Polyethylene (HDPE) and Cross-Linked Polyethylene (XLPE): These materials can be manufactured to be translucent, allowing light to pass through and the water level to be seen, especially in smaller to medium-sized tanks. They offer excellent chemical resistance and durability.

- Fiberglass Reinforced Plastic (FRP) with Sight Strips: Large FRP tanks often integrate a thick, clear acrylic or polycarbonate 'sight window' strip along the side, secured with chemical-resistant seals.

- Advanced Borosilicate Glass and Quartz: Used primarily for high-pressure, high-temperature, or chemically aggressive applications where a sight glass (gauge) is required. These materials ensure **optical clarity** and **chemical inertness**.

The Role of External Gauge Systems (Sight Glasses)

For opaque metal or concrete tanks, the principle of transparency is applied through external gauge systems:

- Tubular Sight Gauges: A simple, vertical transparent tube connected to the top and bottom of the main tank, allowing the water level inside the tube to equalize with the water level inside the tank.

- Reflex and Transparent Flat Gauges: These are robust systems that use prisms (reflex) or two sheets of glass (transparent) to allow a clear view of the liquid level, often used for steam boilers and high-pressure vessels.

Maintenance and Safety Considerations for Transparent Systems

While offering low maintenance, transparent materials require periodic checks for:

- UV Degradation: Sunlight exposure can cause some polymers to cloud over time, reducing visibility. Proper UV-stabilization is essential.

- Scaling and Bio-Fouling: In hard water or untreated water applications, mineral scale or biofilm can build up on the inner surface of the transparent material, which must be cleaned to maintain clarity.

The Operational and Financial Benefits

(**NOTE TO EXPAND**: This section should detail the economic advantages: reduction in manual labor costs, prevention of costly spills/run-dry scenarios, extending equipment life by preventing cavitation, and compliance with environmental regulations.)

Enhanced Safety and Compliance

(**NOTE TO EXPAND**: Focus on safety—no need for physical tank entry for level verification. Discuss compliance—accurate, verifiable records aid regulatory reporting.)

Real-World Applications of Clear Monitoring

(**NOTE TO EXPAND**: Provide specific examples: 1. **Municipal Water:** Monitoring chlorine contact time/levels. 2. **Chemical Industry:** Safely measuring corrosive liquids. 3. **Agriculture:** Tracking fertilizer/pesticide concentrates in nurse tanks.)

Conclusion: The Future is Clear

(**NOTE TO EXPAND**: Summarize the key argument. Tank transparency is a fundamental design shift that promotes reliability, reduces risk, and seamlessly integrates with the next generation of IoT monitoring technology. It is a clear path toward more efficient and safer liquid management.)